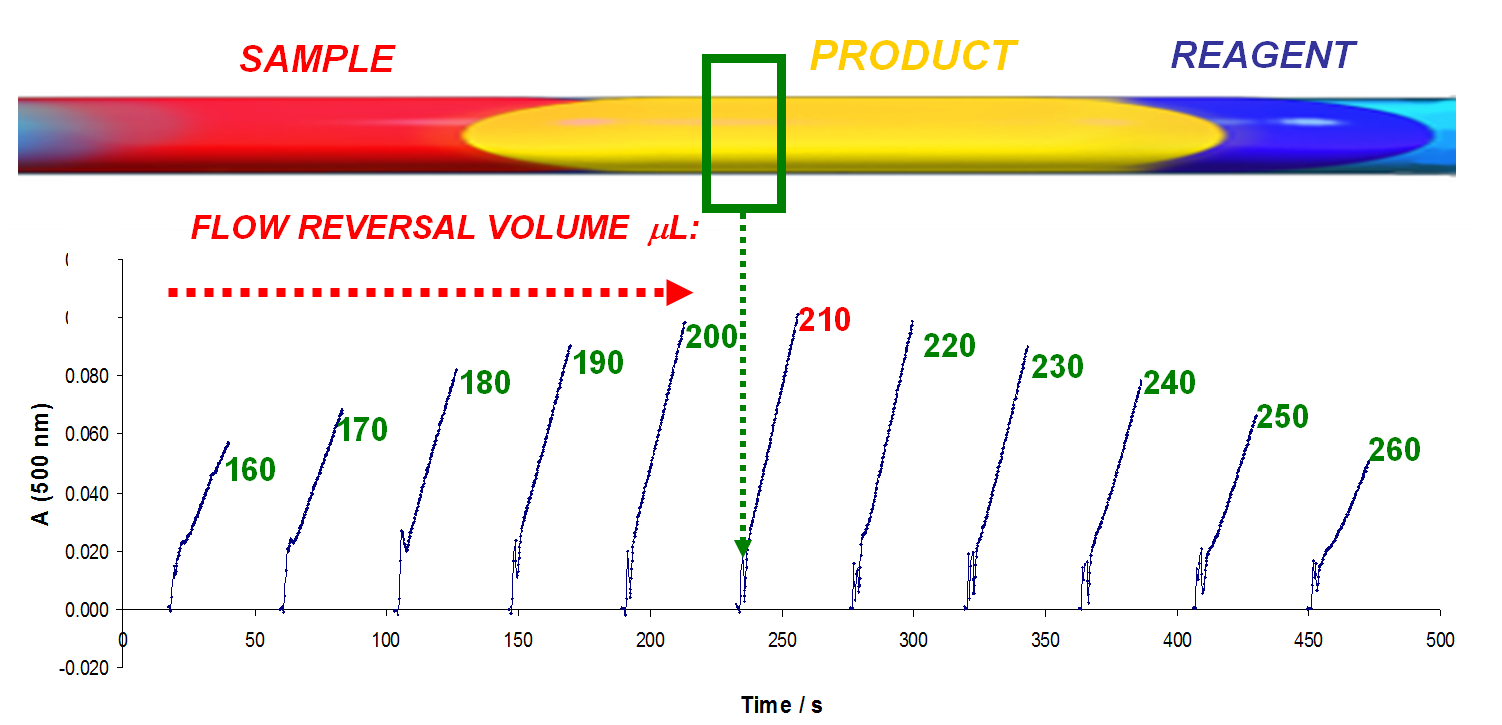

Flow reversal volume defines how far the reacting mixture will travel back from the holding coil, through the multiposition valve and into the flow cell. Too small reversal volume will fail to transport the product into the flow cell, too large volume will flush the product past the detector. In this experiment of 210 mL flow reversal volume, the reaction mixture is transported with optimized glucose/reagent ratio into the flow cell, as shown by the maximized slope of the reaction rate curve. AUTOMATED optimization of stop flow SI protocol (Carroll 2007, Table 3) is described in detail, as a laboratory student exercise.

Optimizing Sample/Reagent Ratio

2.2.9.

Method: glucose oxidase quinoneimine dye. 400 ppm Glucose, sample volume 30 ÁL, reagent volume 80 ÁL, spacer volume 100 ÁL, stop flow 20 seconds. The entire run was obtained automatically.

A.Carroll et al. J. Flow Injection Anal., Vol. 24, No. 2 (2007) 103